The other way to set the fuel height is less accurate, but more convenient, especially if the carbs are already taken apart. That method specifies the height of the float above the bowl mating surface when the carbs are upside down. The height is measured when the tongue of the float frame just barely contacts the tip of the fuel valve needle. The height specified is 27mm. It has been found experimentally that 28mm seems to work better nowadays. Perhaps ethanol is lighter than gasoline. That could explain the difference.

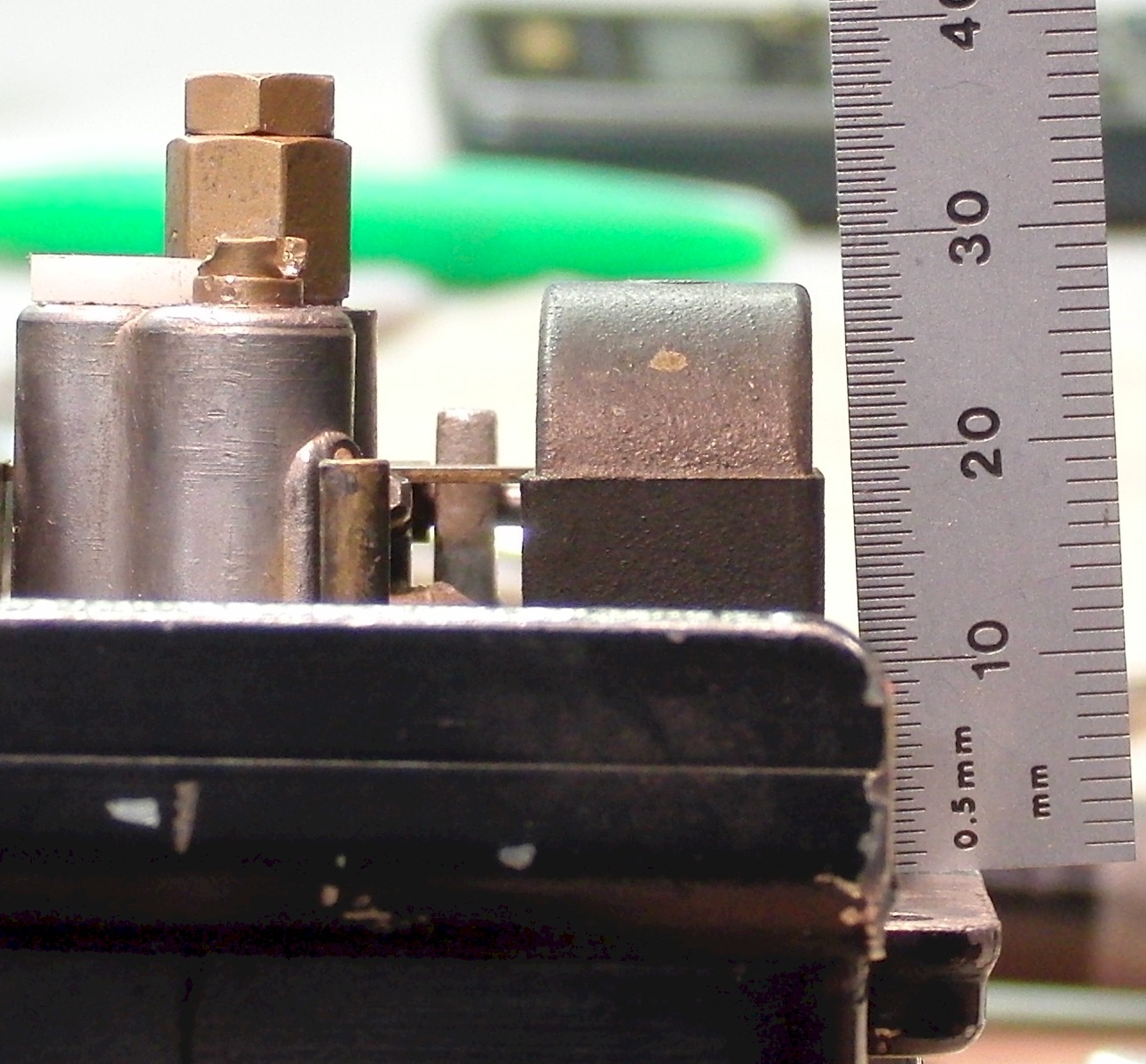

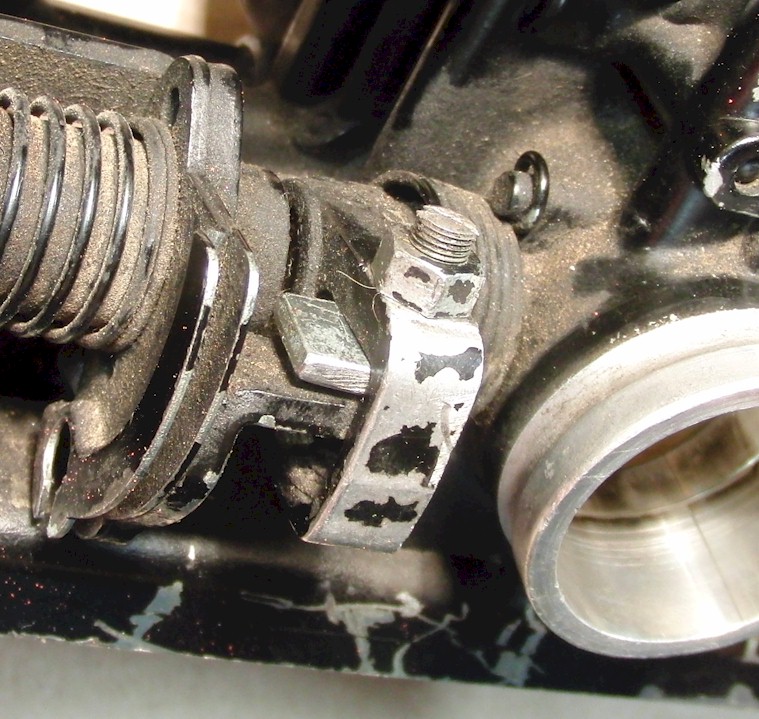

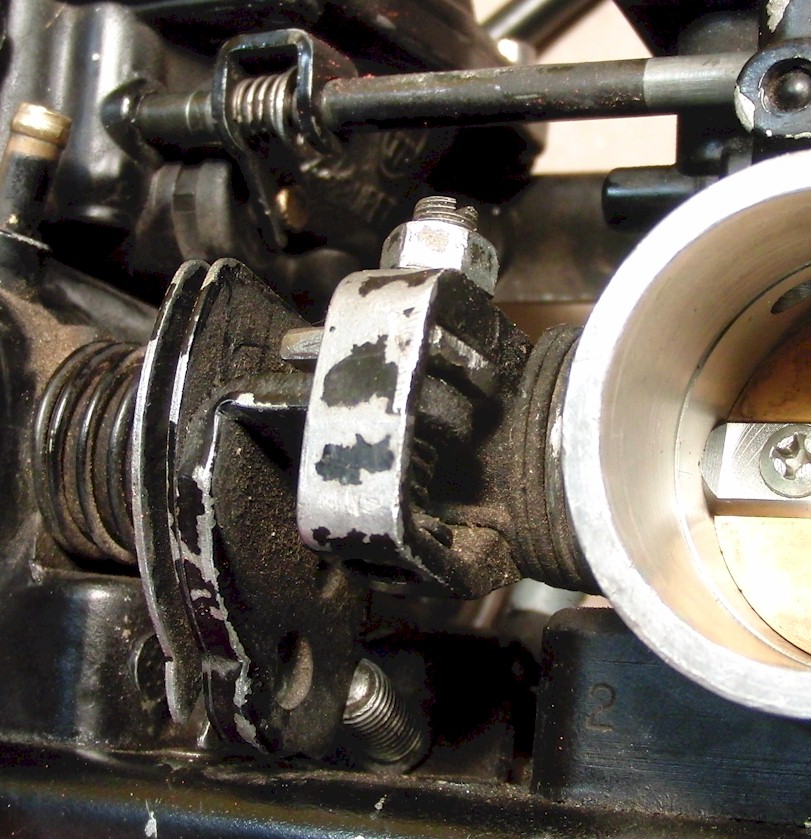

First up are some tools for syncing the carbs on the bike. The sync screws and locknuts (8mm) are a long reach when on the bike, but some cheap home-modified tools can make it easy. First you need a couple specific screwdrivers. One is a multi-driver usually available at home centers. This Buck Bros., orange-handled screwdriver is useful because the main steel tube has a hex shape at each end, which is probably nominally 5/16", but fits the 8mm locknut of the sync screws nicely. They don't need to be very tight, as a matter of fact they will strip out the aluminum linkage if care is not taken. (See the repair done near the end of this page.)

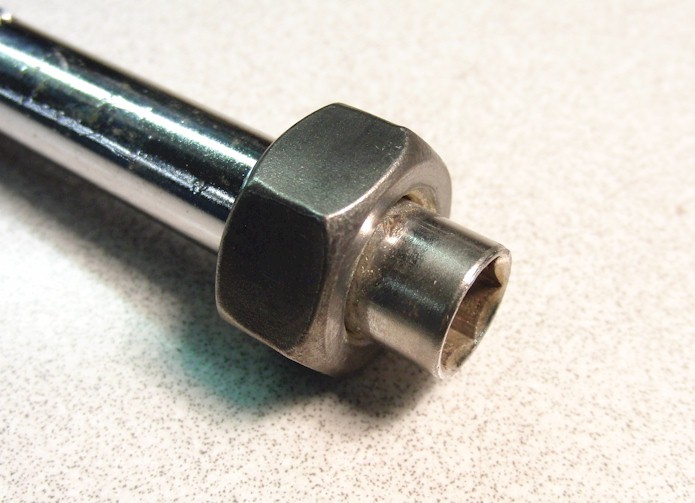

To use the driver, the detent ball and spring must be removed. There may also be some sort of plug near the spring and ball in the middle of the hex tube. The hex tube has a narrow section in the middle that must be opened up for the screwdriver to fit through. A 1/4" drill bit, inserted through the hex tube the long way, works well to drill out the center section of the tube. Be careful to drill with little pressure as the drill bit may get entangled with the spring and or ball bearing. It is probably best to drill a little bit from each end of the tube. Drilling the tube can be tricky so use a vise grip or something to hold the tube rather than bare hands. After drilling, the spring and ball can be pushed out.

Then an appropriate, long skinny screwdriver can be used through the center of the hex tube. To ensure a decent grip on the hex tube, a large nut was heated red hot and pressed onto the tube. Finger tightness on the large nut is all that is needed to lock the sync screws.

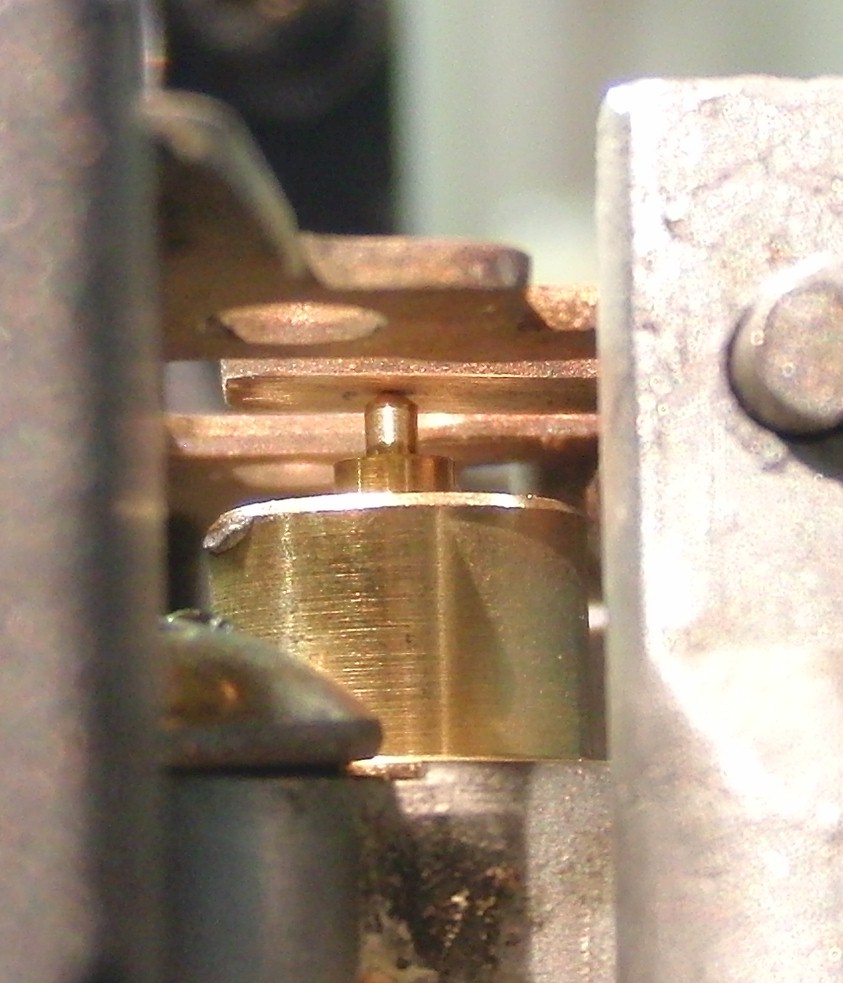

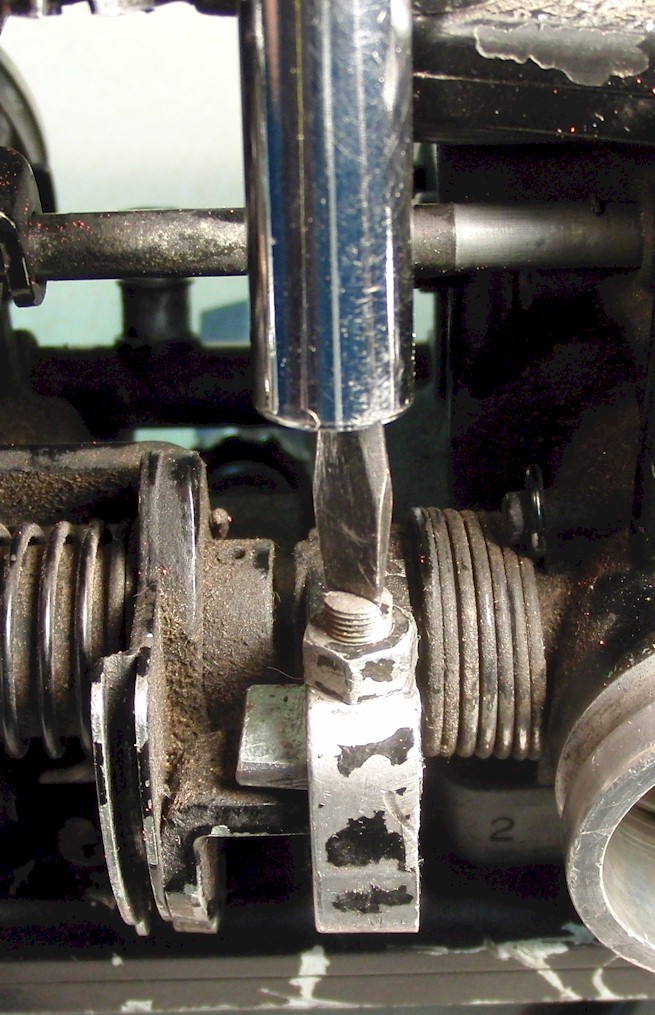

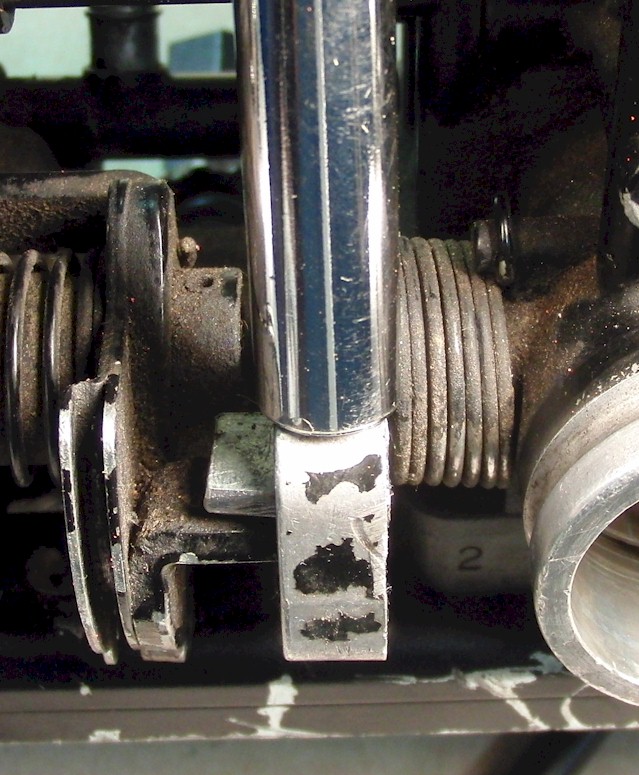

Make sure the screwdriver you select fully seats into the sync screw as seen below.

The hex tube slides over the nut while the screwdriver is engaged with the screw. This makes syncing much simpler.

Here is a set of tiny bottle brushes that proved very useful for cleaning out the bleed pipes and jet galleries.

It is from American Science and Surplus, so they should be readily available online.

Click on the images below to get a closer view.