When the system is in good working order, the bike will start up easily, but may still have difficulties with erratic idle behavior. There is a modification that can be done to the fast-idle control in order to make the choke behavior more controllable. Fast-idle screw mod .

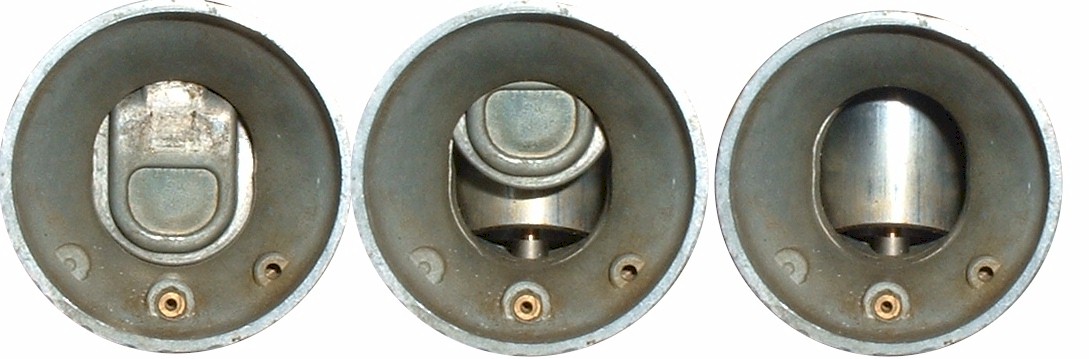

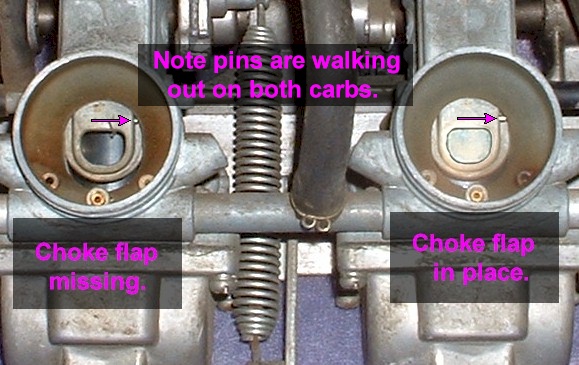

The first problem is that the flaps themselves fall off and get sucked into the engine. Stange as this may sound, often the flaps make their way through the engine and cause no problems at all. It must somehow get out through the exhaust system. However, occasionally the flap will get stuck in a valve and the head will have to be removed to clean out the remains of the flap. Looking into the intakes of the TK-22 carbs, while the choke is activated, will show right away if the flaps are missing.

Some KZ550 owners have fixed the missing flaps by completely sealing the flap opening with epoxy. They have reported success with this method. Using this method requires much more precise control of the choke lever by the user during cold starts. Essentially, the choke becomes a 100% mechanical choke. After a little trial and error, the rider gets a "feel" for how to do it, and it becomes second nature. This is actually an old trick for starting engines before the days of automatic chokes.

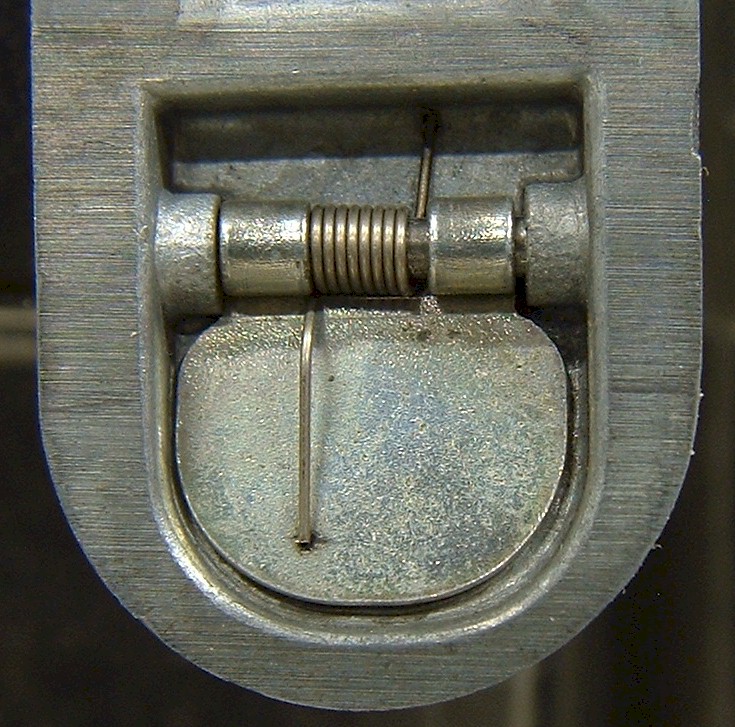

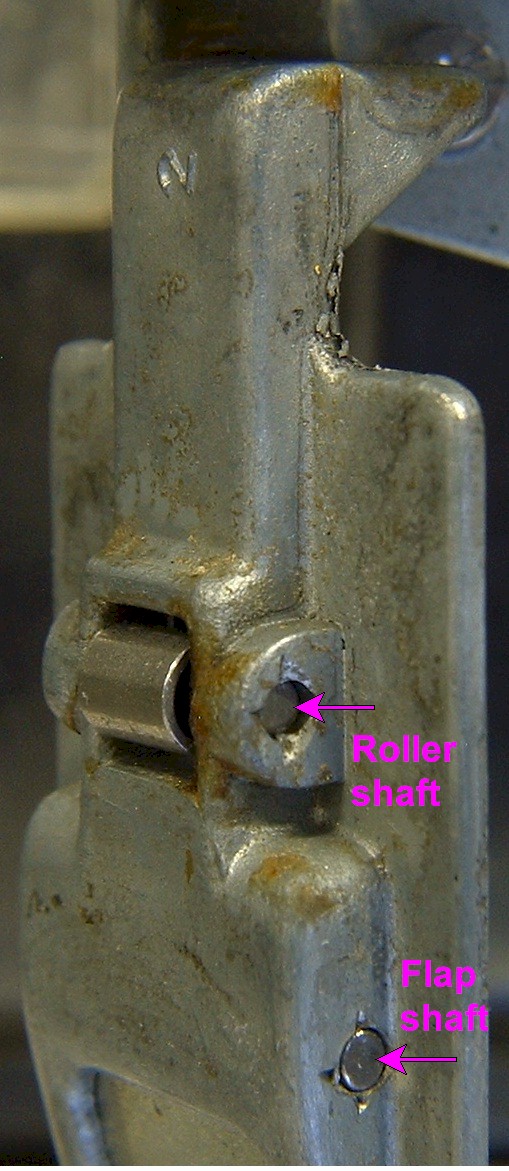

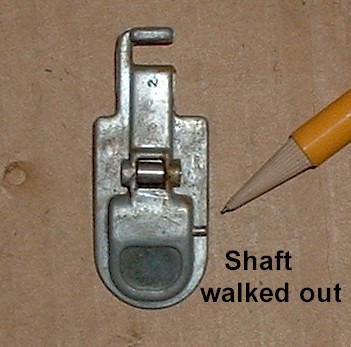

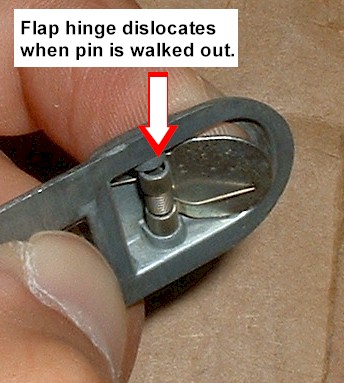

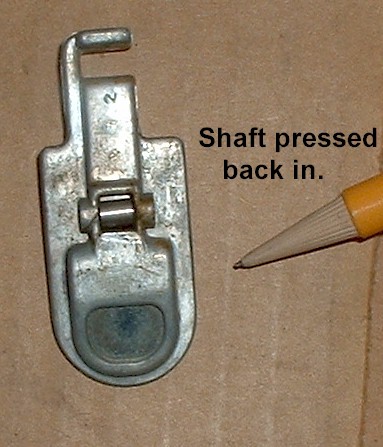

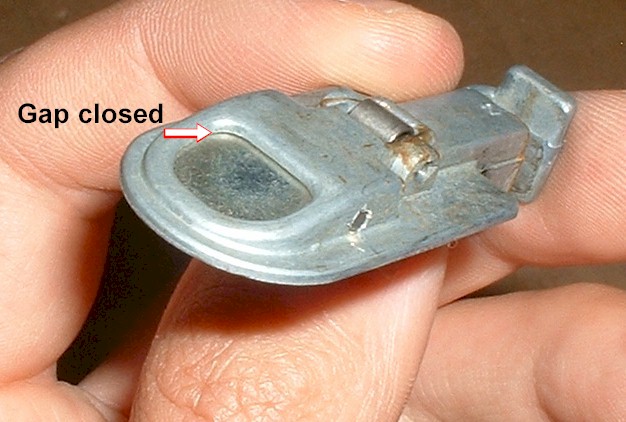

There is another way the flaps can make the bike more difficult to start. This is when the shafts walk out partially, but the flaps still stay in place. If the shafts walk out partially, the flaps and springs will no longer be in alignment. Even though the shaft is still there, the flaps will not operate correctly. They may bind up in a way so that they do not close all the way, or may not move at all.

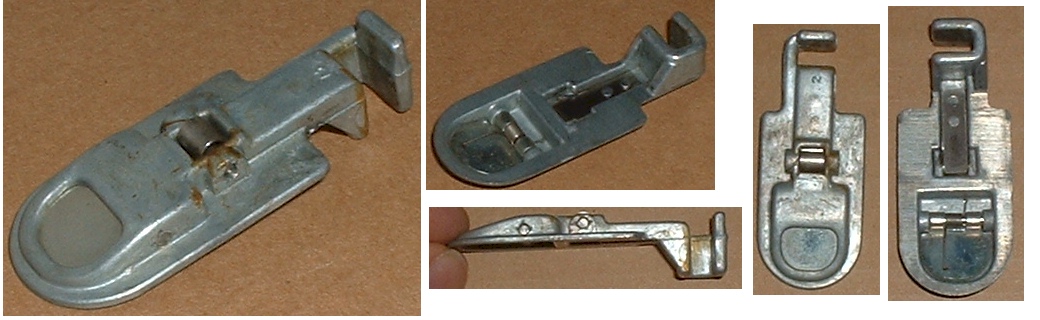

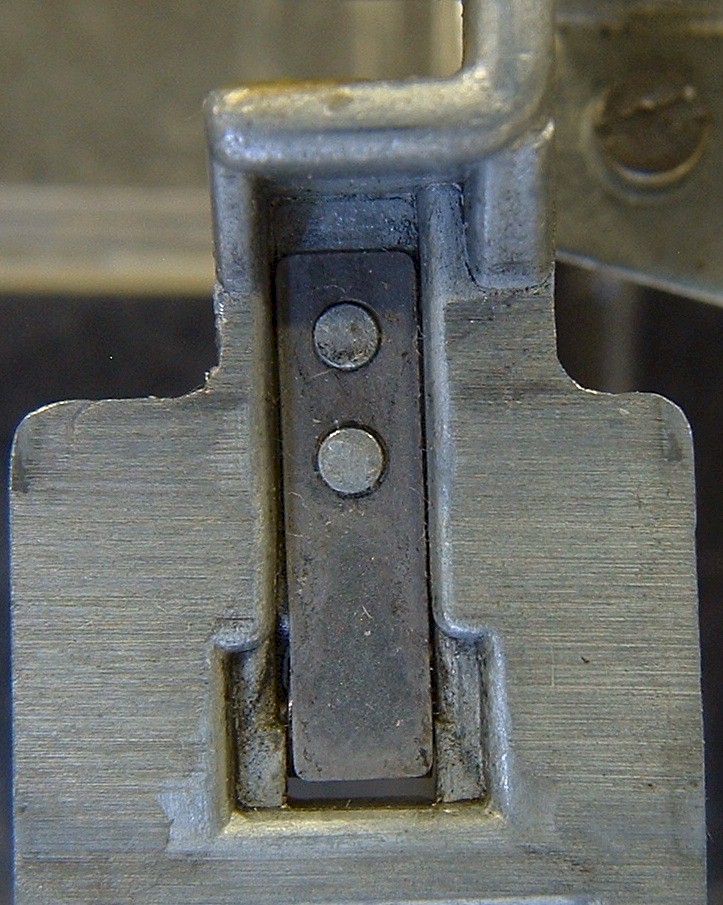

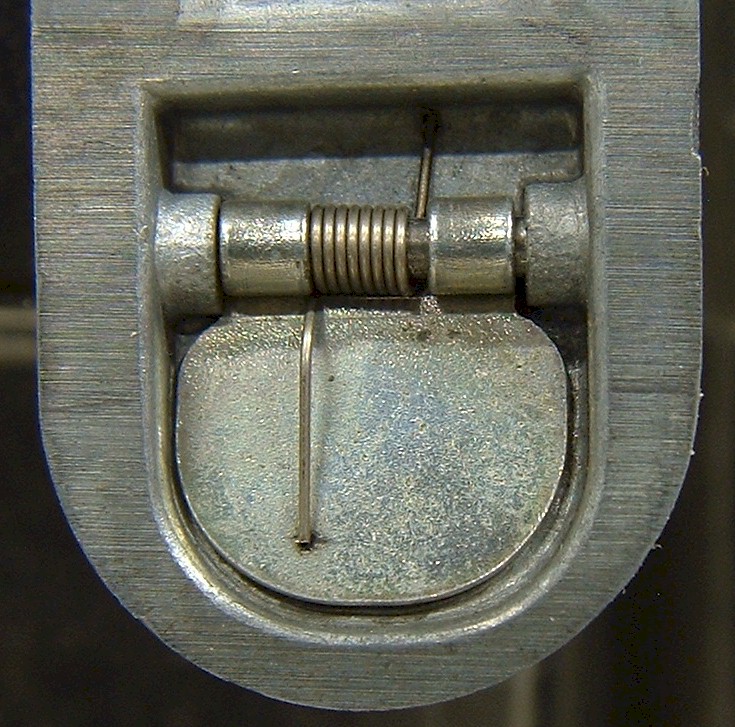

Another problem is that the hinge-curl on the flaps tends to break off. If both break off, then the flap is going into the engine. Here is a complete flap, on the left, shown next to a flap with one hinge broken, on the right.

Another solution may be to make new choke plates in the form of a part with no flaps, springs, rollers, or shafts. The flap opening would be blanked, so as to work the way the sealed flap remedy (mentioned above) works. Perhaps more detents could be drilled into the choke control lever so the choke can be set to several different positions. The part could possibly be die cast or simply carved out in a CNC machine.

For now, the best overall soultion is probably to make replacement flaps. See below for newly made replacement flaps.

Replacement choke flaps are available here. There are only a few left.

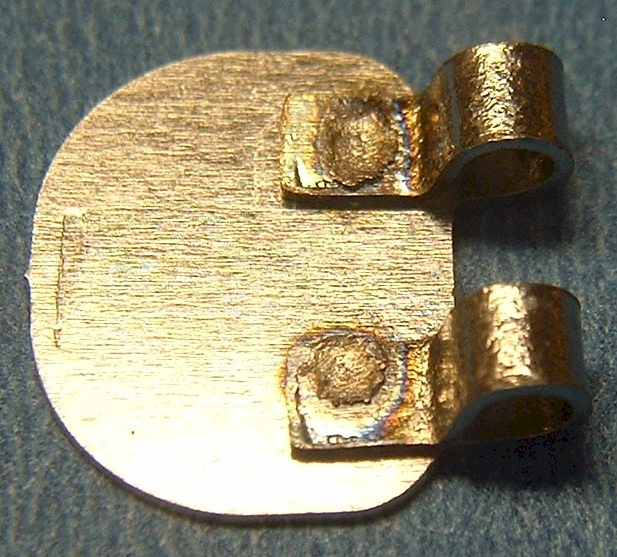

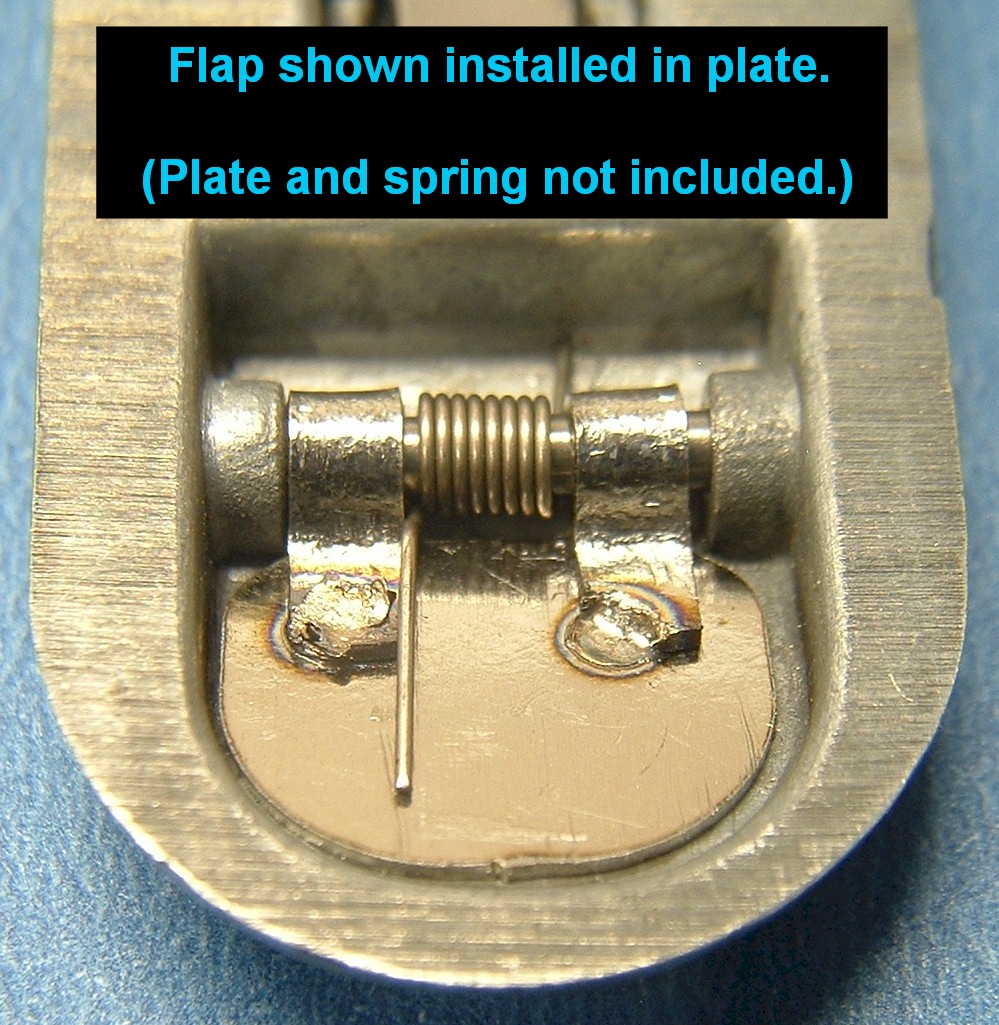

These are the choke flap only. (No spring, shaft, or plate included.)

Made of 304 stainless steel, these are a new design where the hinges are spot welded for extra support.

These are NOT a Kawasaki factory part.

Fits:

1980 KZ550A1

1981 KZ550A2

1982 KZ550A3

1980 KZ550C1

1981 KZ550C2

1982 KZ550C3

1983 KZ550C4

1981 KZ550D1

$16 for first one.

$12 for each additional.

That includes shipping to the lower 48 states in the U.S.

Paypal accepted.

Contact Loudhvx@yahoo.com